Do you wish to enhance your order fulfillment procedure? If yes, your ultimate solution is a complex procedure, item fulfillment NetSuite that includes all aspects from the sale point to shipment to the final consumer. NetSuite Solve item fulfillment issues help your business to manage inventory, orders, fulfillment, and shipping.

Businesses are constantly looking for strategies to improve the fulfillment procedure and satisfy customer needs for quick deliveries while increasing accuracy. Order fulfillment by NetSuite guarantees precise and prompt delivery of client orders.

Companies reduce inefficiencies and improve productivity by standardizing and streamlining fulfillment procedures. Employees are directed via the fulfillment cycle utilizing pick-and-pack principles and techniques, guaranteeing that stock is handled in compliance with business strategy.

Organizations might further tailor and regulate how orders are executed. It will be done by choosing one or more picking kinds, creating a wave distribution model, and determining wave statuses. Amid all this, organizations face numerous order Item fulfillment issues that are discussed as follows, along with the ways to solve them:

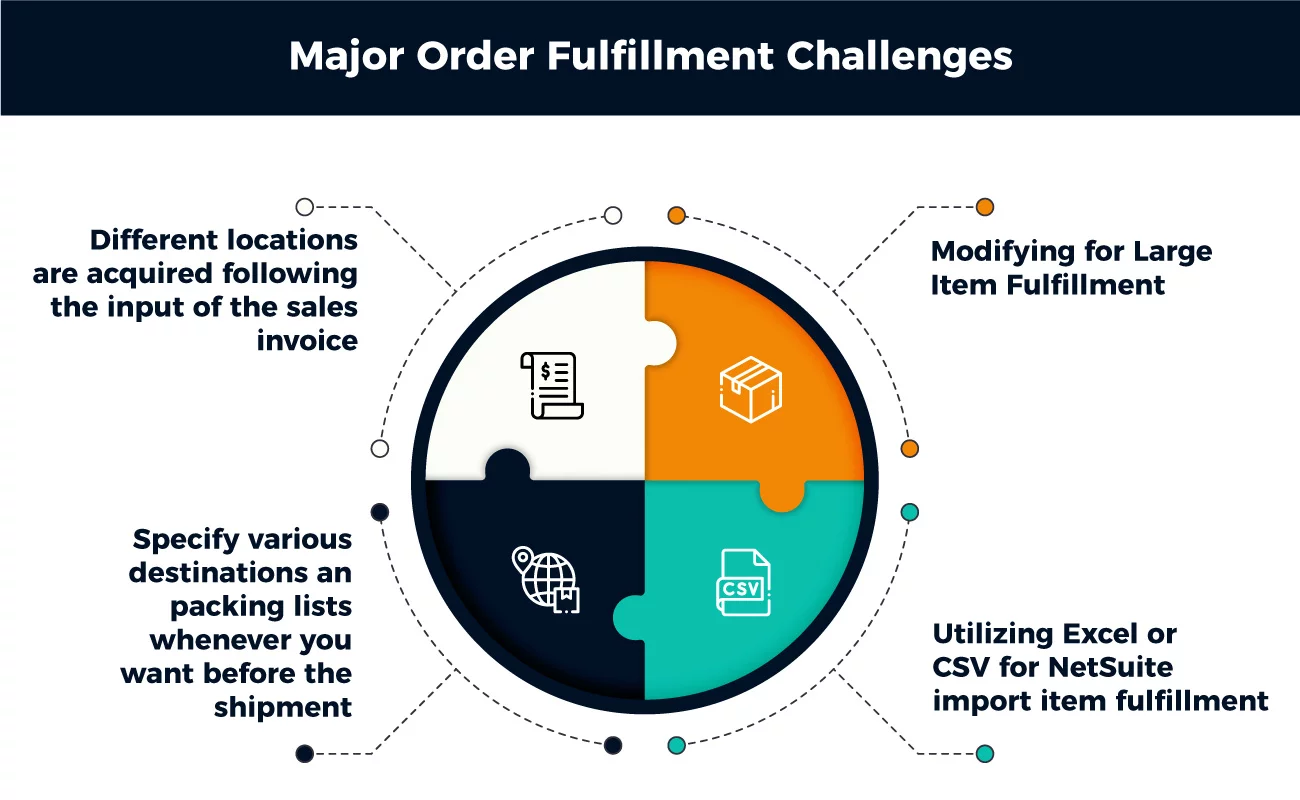

Typical Order Fulfillment Issues

1. Modifying for Large Item Fulfillment

Several businesses must feed tracking data into already-completed orders or use service providers to handle orders. Another extremely typical necessity is the capacity to change item fulfillment in mass using information from any external information source.

2. Utilizing Excel or CSV for NetSuite Import Item Fulfillment

Item fulfillment details cannot be imported using native NetSuite CSV imports. A technique to mass upload product fulfillment is a significant prerequisite for most firms. This is precisely the case when plenty of fulfillments are required to get issued.

3. Specify Various Destinations And Packing Lists Whenever You Want Before The Shipment

Due to the possibility that each destination might receive a different volume of the goods, it is thus occasionally necessary to create distinct quantities for each shipment. Also, it’s essential to define varying amounts for each fulfillment. The fulfillment staff personnel shall be directed to pack the anticipated volumes of each shipment correctly. It’s if they can determine its parcel amounts for shipment.

4. Different Locations Are Acquired Following The Input Of The Sales Invoice

Numerous requests are obtained, and NetSuite creates invoices from item fulfillment to induce stock or generate purchase requisitions. It’s done even when the delivery locations are unclear during the input point. Several drop ship firms need to be able to accept purchases. These firms then specify the shipment locations at a subsequent time.

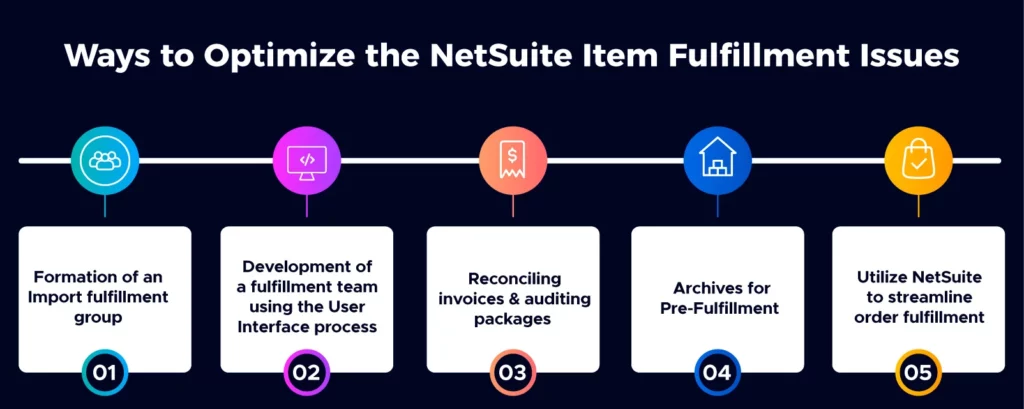

Ways to Optimize the NetSuite Item Fulfillment Issues

1. Formation Of An Import Fulfillment Group

This method deals with the difficulties of possessing numerous ship-to-destinations that call for an import modification. This program is indeed a NetSuite CSV product fulfillment import program. It enables users to integrate object fulfillments, which was previously impossible because NetSuite needed to support it.

To dynamically construct pre-fulfillment data, NetSuite has developed a unique drag-and-drop uploading technique that can take perhaps a .xlsx/ Excel file or even a CSV-formatted document as input. Such pre-upload checks ensure that all essential sections are filled out so each field’s file format corresponds to the corresponding column header.

For US delivery locations, they also run location data validation. Before the uploading procedure commences, certain essential content verifications are initially carried out. It’s to prevent frequent errors and bugs while managing such lists. This pre-fulfillment data can be accessed immediately from the customer orders history after the uploading operation.

2. Development Of A Fulfillment Team

We first created a unique sub-tag for invoice numbers as a first technique. This is to let consumers submit the descriptions of those unit fulfillment products and delivery addresses. Also, this is the best option for users searching for a rapid entry UI to enter location information for an accomplishment of twenty or even less. This simple data patch shall keep records when you establish the fulfillment teams. This record is of the number of parts that still need to be distributed.

This “Specify Pre-Fulfillment Details” option causes a pop-up box to display. The operator can quickly divide and disperse the goods and volumes dispatched to each unique ship-to-destination. Fulfillment teams include the product(s) that must be dispatched to every location and separate shipping modes, shipping dates, shipment goods, and addresses.

The customer may enter data relatively quickly thanks to the straightforward “Copy” and “Add” functions at both the collective fulfillment and item bases. Moreover, to avoid over-dispersion, the area shall flag as incorrect when any user provides an amount for an item higher than the amount that is accessible.

3. Reconciling Invoices And Auditing Packages

The package has several sub-tab searching and audit features. You may use these features to browse through each product transported and ensure that nothing has been left over. The NetSuite item fulfillment issues report contains unmatched aggregate checks and a comparison between all the goods on both columns of the pre-fulfillment data vs. customer orders and the progress of its import procedure.

4. Archives For Pre-Fulfillment

To manage the transportation and allocation of the goods and amounts to be transported to the various sites, NetSuite order management offers two distinct approaches.

- NetSuite Xls Importer: To build all the necessary pre-fulfillment data for bigger volume multi-fulfillments, designers created a NetSuite Xls connection that can be easily dragged and dropped into NetSuite.

- Inter Addresses User Interface: NetSuite improved the customer orders UI to offer a mechanical input technique with quick copying and clone options. This is to enable the User experience simply to navigate for sales invoices with a range of items being delivered to fewer than fifty ship-to destinations.

5. Utilize NetSuite To Streamline Order Fulfillment

More than possessing a fantastic item is required to gain repeat business. That certainly benefits, although order fulfillment procedures can either build or destroy a business in the present quick business world. They significantly influence client satisfaction. By trying to coordinate and organize all the variables involved in order fulfillment, encompassing the whole order processing sequence, an order management software like NetSuite Order Administration helps.

It streamlines order handling and effectively manages inventories across the transaction lifespan. Additionally, this kind of solution offers analytical data, like KPIs and specific other indicators, highlighting your strengths and areas for progress. To ensure you possess the appropriate items in hand and that sales numbers are in line with the stock ordered, the Order Management System must also be linked with stock control solutions.