NetSuite has a page called Demand planning is an integral part of the whole supply chain management process. Using this technique, the company can predict their future demand and, depending upon that, how to customize their product outputs. Also, effective NetSuite Demand Planning enthralled in a company could help you get out of any tricky situation that you face regarding your production supply.

Is your business taking up much time planning the products your production department would manufacture?

Moreover, if you don’t know, effective demand planning is one of the crucial steps to take your company to unimaginable heights. Also, knowing the right amount of stock you need to produce to avoid overstock or storage of products is part of demand planning. However, if you are new to the field of business and don’t have that experience or prior knowledge regarding demand planning. Then, NetSuite could be the ideal destination for you because of its popularity in offering some of the excellent demand planning techniques to its customers.

So, you will get to know why you should choose demand planning NetSuite in this article.

Exclusive Features Of NetSuite Demand Planning

Now, after getting a brief idea about what is the demand planning process. Let us now look at what are the exclusive features and the importance of having a NetSuite demand plan for your company: –

Flexible Forecasting

Calculate demand plans, which can create demand plans automatically. Also, the work of this page includes accessing all the previous demand requirements and estimating the future demand.

Benefits of using NetSuite demand forecasting include: –

- It analyses all the historical data and forecasts a demand plan based on those factors.

- Collecting the actual forecasting data helps identify all the seasonal fluctuations that could be taking place in the future.

- It lets you choose a preferred stock according to your company’s product-to-product base requirements.

- A preferred location for selling can be predicted, which would be essential in your demand plan.

- Lastly, it allows you to review and modify each demand plan after a specific period.

Efficient Supply Plan

Successfully determining your demand plan using the forecasting feature will not be enough for your business. That is why NetSuite also allows you to set an efficient supply plan through its calculated supply plan page.

The benefits of using NetSuite customer demand planning for your supply plan comprise: –

- The supply plan ensures you maintain a schedule for manufacturing and purchasing the additional necessary supplies.

- It tweaks your supply line by recommending buying orders by calculating the lead time and future demand.

- Lead times are an essential feature that will let you know when to purchase any item with increased demand.

- All the necessary calculations regarding your stock safety levels are done throughout the supply chain process.

Maintaining The Level

After knowing about the features of NetSuite planning regarding demand and supply, the following criteria it provides to its customers represent sales and procurement of the company’s products. Also, this feature helps a positive outlook on your business in the long run.

Some of the advantages of using this unique NetSuite customer demand planning feature involve: –

- NetSuite is known to provide some of the best features through its inventory management software compared to others.

- It accurately maintains the right amount of stock needed to meet the expected future demand.

- The pinpoint representation of your expected demand would eliminate the chances of facing loss by injecting more capital than necessary.

- The unique benefit of using this feature is that it can land you exact details of when someone purchased the item when it is shipping, and when it will be delivered.

Conglomerate Of Locations

NetSuite is famous for allowing location access and integrating a multi- locational feature in its inventory management software. Also, this feature would enable businesses to execute easy pick-up and delivery of products, ensuring a steady workflow.

The benefits which you can enjoy upon using features comprise of: –

- Maintaining an excellent shipment includes delivering and picking up the products for a smooth workflow.

- These features would allow you to maintain a warranty and repair checklist of the items.

- The users using the multi-locational feature can set up data for each location, providing an exclusive look into the products’ demand.

- Most importantly, it offers top-class customer service, which ensures the satisfaction levels of the customer at that location are high.

Single Out Your Priorities

Knowing which product would hold more priority compared to another is one of the critical attributes for maintaining a steady demand for the products. Also, keeping this in mind, NetSuite, with its automatic order exception feature, allows business owners to scale out the priority products before.

The advantages which your business can enjoy upon implementing this feature are: –

- The order exception feature would inform your fulfillment department when the production department did not fulfill an order to avoid losses.

- A flag is raised whenever there is product storage, which lets the business merchants know about the situation.

- By reviewing all the supply orders, you can determine if the high-priority sales would arrive on time and location or not.

- The efficient reallocation features recommend substitute locations so that the businesses don’t face overstock in one place and face losses.

Setting Up Of The Items

NetSuite demand planning partner checks each item effectively by looking at its various parameters. Keeping the items list under the inventory management software would allow you to set some settings that would allow a smooth setup of the items. The settings which can be set using the above features include: –

- Safety stock determination

- Resizing methods

- Ensuring a fixed lot size

- Planning of the supply periods

- Type of supply and demand source

- Determining the forward and backward expending days

- Lastly, a reschedule setting

Proper Execution Of Orders

After setting up everything related to the demand, supply, determination of high priority orders, and all the other required things, the last feature that could ensure the process is run smoothly would be the order execution.

The various benefits which order execution feature bestows upon the businesses include: –

- Setting up reminders

- Notification alerts through emails

- Previously saved searches

- A proper schedule of reports

Now, after knowing about some of the features, you can enjoy it if you choose your company’s NetSuite implementation partner or demand planning, partner. Then, let us know look at the four methods that you can integrate with your company depending upon the requirement: –

4 Methods of Projection Offered by NetSuite

1. Moving Average

The moving average method is a calculation that considers the mean of a particular number over a while. Taking up the average seven multiple moving averages instead of weekly patterns would ensure the production process runs seamlessly. It helps provide a vision and target to the business instead of looking at daily numbers that are of no use.

2. Seasonal Averages

As you can already guess, seasonal averages determine the products’ demand, which regular moving averages cannot. The holidays provide a significant demand shift in products; seasonal averages can help determine those. You can compare the previous season’s sales which would provide an idea about this season’s demand for that item.

3. Econometric Methods

The different econometric methods are used for various methods by businesses and are not subjected to a single use. It is a part of the regression analysis that uses various statistical data and hypotheses to provide the best economic model for the business.

Also, one of the common usages of this econometric model by various businesses includes calculating the effect of increasing the minimum wage of the employees of the company. Moreover, this is in comparison to other companies in the same picture. Also, it can not only forecast the demand for the product economically but also take care of another economic side of the business.

4. Gradient Boosting

Gradient boosting is essential to businesses’ machine learning techniques for various prediction tasks. Also, it is known for accumulating all the small and simple methods for producing a more significant forecast.

Popularly, the simple methods could be inaccurate, but gradient boosting combines all those simple methods and creates accurate data for businesses.

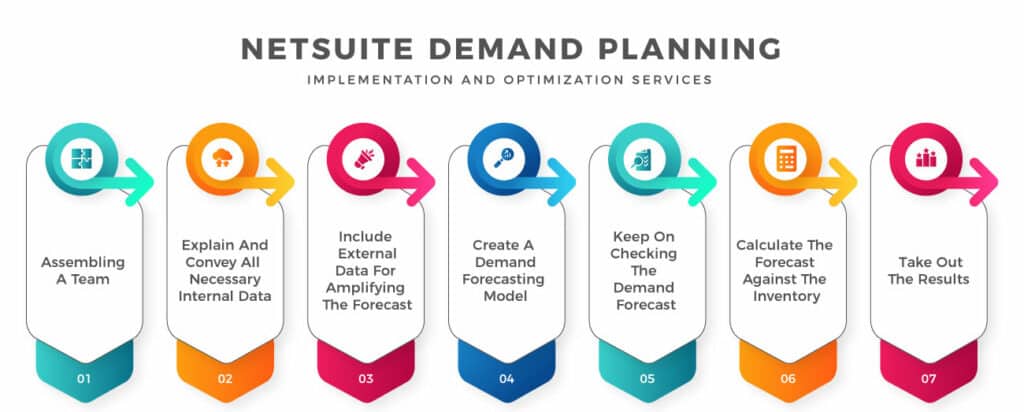

7 Steps to Impactful Demand Planning

Demand planning could quickly become hectic in your company, and not following the proper steps could make it almost impossible to deploy. So, here are the seven steps that could help you perfectly integrate the NetSuite demand planning depending on your company’s requirements: –

1. Assembling A Team

The first step towards impact demand planning would be assembling and ensuring the team you get together has proper roles and responsibilities. Assigning each team member different tasks would ensure all the various inventories of the business are appropriately looked after.

2. Explain And Convey All Necessary Internal Data

All the employees from various departments of the business involved in demand planning need to agree on the necessary data to be added to the NetSuite demand planning for developing a precise forecast.

As necessary, the team allocated for the demand planning must include the internal data from the sales, marketing, and production departments.

3. Include External Data For Amplifying The Forecast

Along with the internal data, external data is crucial for culminating a perfect forecast and demand plan for your company. The external data that needs to be added could comprise when products are getting delivered and if the products sold by your company satisfy the customers, to name a few.

4. Create A Demand Forecasting Model

After collecting all the necessary internal and external, the next step would be to develop a unique demand forecasting model that best suits your company.

The various demand planning software available on the market could help you carry out the process seamlessly.

5. Keep On Checking The Demand Forecast

Choosing to stay static with your company’s demand forecasting could be wrong. Keep rechecking, reanalyzing, and reviewing all the necessary data with the company’s team and shareholders.

Add all the relevant recent data you collected that could impact your demand forecast and recheck them in perfect alignment with the financial budget of your business.

6. Calculate The Forecast Against The Inventory

Keep a close towards your inventory and calculate if the predicted forecast could be fulfilled at the required time. Now, add some safety stock into the inventory and keep consulting your vendors for delivery of the products at the allocated timeline.

7. Take Out The Results

Use different key performance indicators or KPIs that could help you measure the accuracy and effectiveness of the demand forecast made by your company. Keeping a close eye on the performance of the demand plan could help you identify any mistakes and change them as required.

Conclusion

Demand and supply are crucial steps for planning an efficient business production model for your company. Also, including the demand and supply plans, NetSuite demand planning features are known for providing various other techniques, as mentioned in the above article. Moreover, these unique features would ensure your production department goes through a seamless process and experience an efficient workflow.

In addition, NetSuite also offers its customers various choices from which they can choose a demand forecasting method that perfectly suits their business plan and objectives. Also, as you have already read some of the methods mentioned above, hopefully, it will help you decide on one for yourself effectively.