The precise inventory forecasting remains invaluable, particularly at times when consumer demand and supply chain requirements are going through rapid changes. Delivering the right inventory forecasts involves utilising a complex mix of data analysis, business experience and data-driven insights on customers. Forecasting also needs experts capable of making data-driven predictions by taking into account all factors resulting in a hike or downturn in future demand.

To be more precise, inventory forecasting relies heavily on data and data-driven insights to assess the required inventory for predicting future demands. Precise forecasting gives businesses an edge in respect of timely fulfilment of customer orders while spending adequately on inventory. The inventory management software small business houses use to try to have moderate results in terms of ensuring data-driven results.

In a survey of 255 companies looking to purchase ERP software, 67% identified inventory and distribution as the most critical ERP function.

Efficient inventory forecasting can actually make the difference between smooth order fulfilment resulting in streamlined revenue generation and heaps of unsold products that consume the available business resources. By forecasting, the surge or dip in sales companies can utilize their resources and ensure better profitability. In terms of precision and accuracy, robust ERP automation solutions like NetSuite supply chain management can ensure optimum efficiency.

Accurate and streamlined inventory forecasting also helps ensure customer satisfaction and supplier satisfaction by reducing the risk of stock exhaustion. While ensuring smooth availability of products at sales counters it also enhances the utilisation of resources by preventing piling of stocks.

Here through the rest of this post, we are going to explain the definition and various types of inventory forecasting, the way it works, the key challenges corresponding to inventory management and how accurate forecasting addresses these challenges.

What Is Inventory Forecasting?

Inventory forecasting which is also referred to often as demand planning represents the use of past data, consumption trends and various triggers and events to make accurate predictions of required inventory levels to fulfil the demands of the future. When such forecasting is accurate, it helps businesses to have enough stock for fulfilling customer orders while utilising just the right resources for maintaining the inventory.

How Does Inventory Forecasting Take Place?

Inventory forecasting basically focuses on a particular period in the future to predict the demands accurately so that enough stock can be ensured to fulfil the demands at the right time. Three main aspects that this forecasting should take into account include respectively the forecasting period, the basic or average demand and the variable factors and trends.

As for the forecast period, the wider a period the company chooses to focus upon, there is less likelihood for the forecast to be realistic. The market fluctuations are responsible for this uncertainty. When a forecast period is just one month, the results can be more accurate as fluctuations can be limited. In the case of forecasting for a complete year of time, there can be wider fluctuations.

When asked to select areas where ERP produced ROI, the top three answers were reduced IT costs (40%), reduced inventory levels (38%) and reduced cycle time (35%).

The average or base demand is figured out based on the sales in the previous 30 days or a similar period. The inventory software small business enterprises use mostly focus on a limited threshold of time for better accuracy.

The last but not the least element of variable factors and trends is the most crucial aspect that deserves meticulous calculation and predictive abilities to handle. Apart from various international market influences, seasonal aspects, events, emerging supply chain challenges also matter a lot in impacting the forecasting.

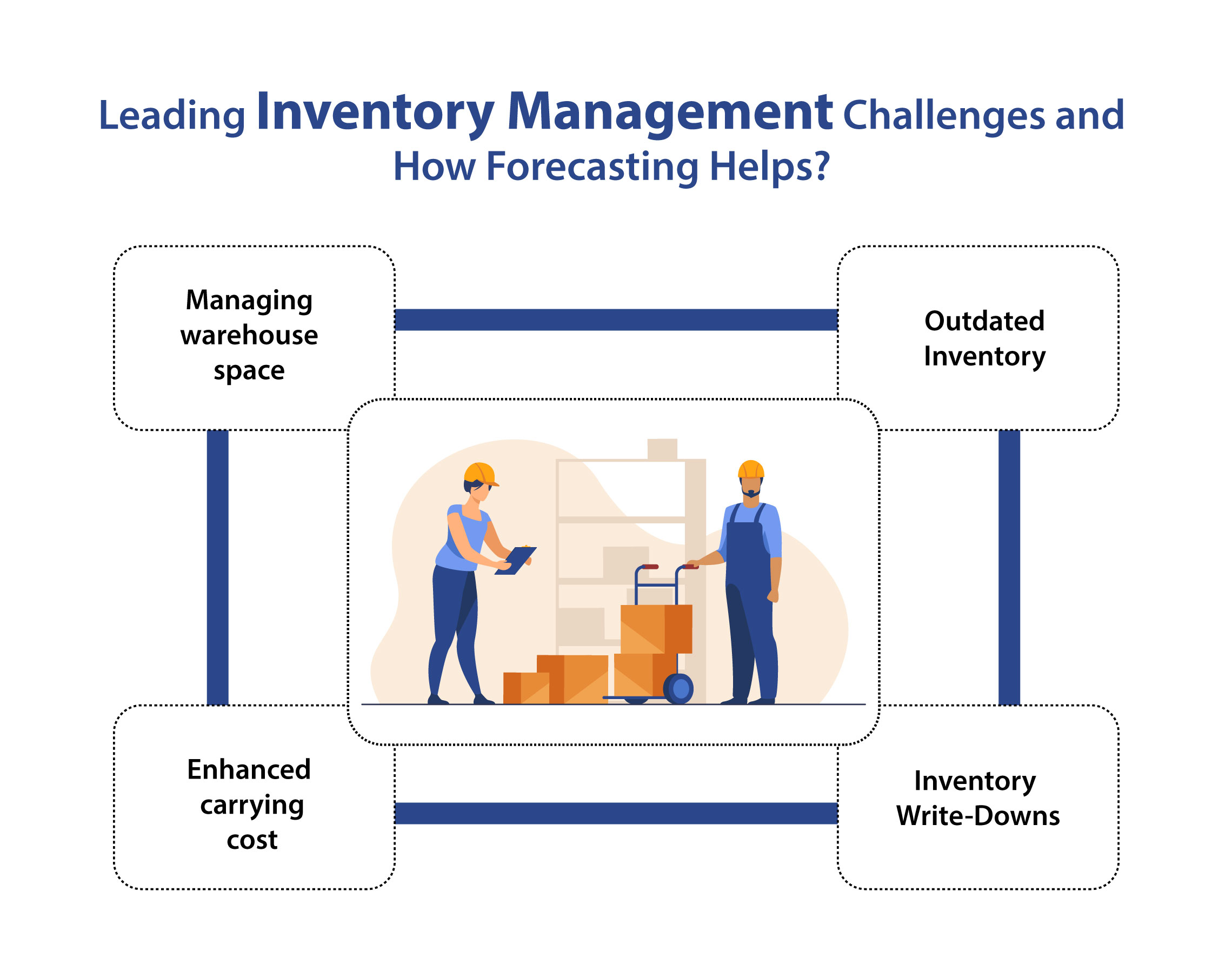

Leading Inventory Management Challenges and How Forecasting Helps?

Inventory management is always a daunting task irrespective of the industry. The inventory management process and the resulting impact influences the business results. But for inventory forecasting to be really successful it is important to consider the key challenges for managing inventory. Here we are going to explain these challenges and the ways forecasting helps in dealing with them.

Managing Warehouse Space

The most crucial challenge for inventory management comes from warehouse space considerations. Since the inventory is stored in the warehouse space and the goods are constantly in motion, accommodating space as per the changing inventory needs is a continuous challenge.

Apart from picking and packaging goods, the management of the warehouse space only is no less challenging. This is where accurate inventory management and forecasting ensures creating enough space to accommodate inventory with the right quantity and as per the demand of the time. NetSuite ERP inventory system streamlines the entire process of forecasting and syncs with warehouse space management.

Outdated Inventory

In the industry, obsolete or outdated inventory is also called dead inventory. Since a business remains uncertain of using the same or finding enough demand for the same, the inventory is considered obsolete or a burden. Such inventory can really impact the business revenue, growth prospects and financial output of a company. As per the assessment across industries, it has been found that around one fifth to one-third of inventories remains obsolete. These goods only add to the losses of a company.

The outdated or obsolete inventory mainly results from inaccurate forecasting and faulty inventory planning. Since businesses make huge losses because of obsolete inventory, accurate and precise inventory forecasting offered by some of the best inventory management ERP systems like NetSuite can be very effective to deal with this challenge.

Enhanced Carrying Cost

Another major concerning area is the enhanced Inventory carrying cost that adds to the overall operational cost. The cost of transportation, handling, shelving, labour, taxation, insurance, depreciation, replacement, damage and shrinkage continues to increase based upon the holding time and other variable factors.

This is why carrying cost still remains one of the most crucial inventory management and forecasting challenges that most businesses need to deal with frequently. By having a powerful and accurate inventory management and forecasting solution in place this carrying cost can be reduced to a minimum. For example, the NetSuite inventory management solution provides comprehensive visibility of the entire sales funnel and accordingly ensures lower inventory holding time resulting in the least carrying cost.

Inventory Write-Downs

The inventory write-down refers to the decreased value of the inventory stock compared with the current market prices. This is ascertained by the accounting process and such a situation often occurs when prolonged holding time ultimately results in the reduction of market value for the stocked goods.

The most time tested strategy to reduce the inventory write-downs is to avoid excess ordering while regularly reviewing the order frequency and tracking demands. These are exactly what a capable inventory forecasting system does. By simply predicting the right inventory needs at the right time, it can ensure faster sales movement at the current market rate.

Recapping The Key Advantages of Inventory Forecasting

So how major inventory control challenges are overcome by accurate inventory forecasting, we have explained. Let us now have a quick look at the key inventory forecasting benefits.

Precision

Thanks to an automated inventory forecasting system you need to rely less on manual labour resulting in fewer data errors. The use of automation coupled up with trend analysis also helps in detecting items that are out-of-stock.

Cost Saving

Inventory forecasting also helps in maintaining the correct amount of stock on hand at the time of need and thus you don’t need to delegate unnecessary resources behind stocks that consume shelves without being moved.

Higher revenue

By syncing the current stock information with the business objectives and sales targets, you can monitor and push sales movement in real-time. This in the end ensures higher sales output with more resource utilisation resulting in higher revenue outcomes.

Higher Quality and Customer Satisfaction

Accurate inventory stock ensures preventing obsolete stock resulting in higher product quality and more customer satisfaction.

Business Process Optimization

Modern inventory management and forecasting solutions powered by real-time data tracking abilities can help business process automation with their real-time data feedback and precise insights. This ensures keeping a business updated with the latest data and requirements.

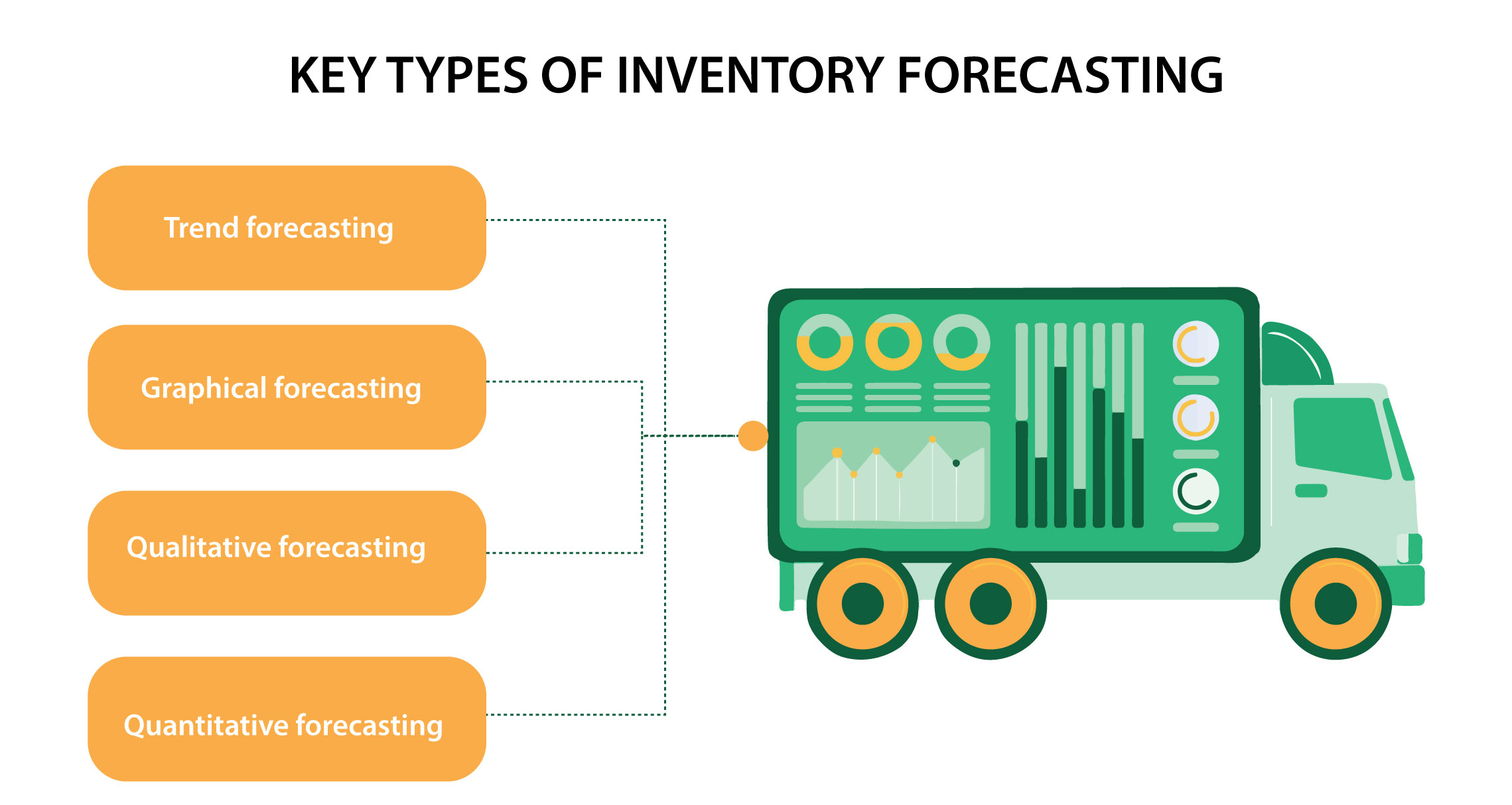

Key Types of Inventory Forecasting

So, you have already understood the importance of inventory forecasting for any business process. You have already known that inventory forecasting does an invaluable job by ensuring proper resource utilisation while pushing product movement and sales as per the evolving demands. But there are different formulas to implement inventory forecasting and one needs to choose the right one for his industry or business type.

Let’s have a quick look at the key types of inventory forecasting. Remember, each of these forecasting methods involves a different formula.

Trend forecasting

Trends refer to the market-driven changes that affect the demand for a product for a particular time. By forecasting, by taking these trends or market-driven changes into consideration this method actually tries to forecast the accurate sales output. This forecasting method gives insights into the future purchasing patterns of the customers.

Graphical forecasting

This method presents the same trend forecasting data into graphical visuals showcasing the peaks and dips. Just because this method showcases the information and data-driven insights in a more visually engaging and quick to grab manner, many forecasters prefer this method. Graphical forecasting provides the data patterns in a visual manner.

Qualitative Forecasting

This forecasting method is only effective when a business doesn’t have much historical data to analyse and draw insights. As per this method the company directly gathers data from customers and target audience. This method involves surveying focus groups and carrying out market research. In the end, forecasters draw patterns or models from this pool of data.

Quantitative Forecasting

This forecasting method is regarded to be more effective as it uses past numerical business information and sales data to draw data-driven insights and patterns of sales movement. As per this forecasting method more past data, a business is exposed to, the higher forecasting precision it can expect. The time-series forecasting that uses the volume of data collected within a timeframe, is a great example of quantitative forecasting.

What Forecasting Method Should You Choose?

Now when it is about choosing the right forecasting method for your business, you need to consider your available past business and inventory data or the new data that you can collect for the purpose of forecasting. If you have an established business brand that is in operation for years, a quantitative forecasting approach will be far more effective just because you have a lot of quantitative data corresponding to the sales and inventory.

For new businesses and startups, it is better, to begin with, a qualitative forecasting approach involving market research and collecting fresh customer information. If you need to streamline inventory forecasting with ERP automation systems like NetSuite, you can rely on the NetSuite implementation companies to choose the right approach based upon your industry need.

In this respect, it is important to remember that the most effective forecasting methods always use a mix of several different methods and types of data. While the quantitative approach helps the forecasters with something to make a convincing start. In certain contexts where enough data is not available, a qualitative approach can be useful to create the model from scratch. So, within an industry in different contexts, you can use two different forecasting methods.

Conclusion

Having enough inventory to fulfil demand is absolutely fine. But having more enough or less than enough inventory needs can either make business waste resources or compromise on sales opportunities. This is precisely why inventory forecasting is so important a part of modern business automation systems.

Learn More:

Revamp Your Store Operations With NetSuite WMS Solutions

How NetSuite Strengthens The Link Between Inventory Management and Supply Chain Management?